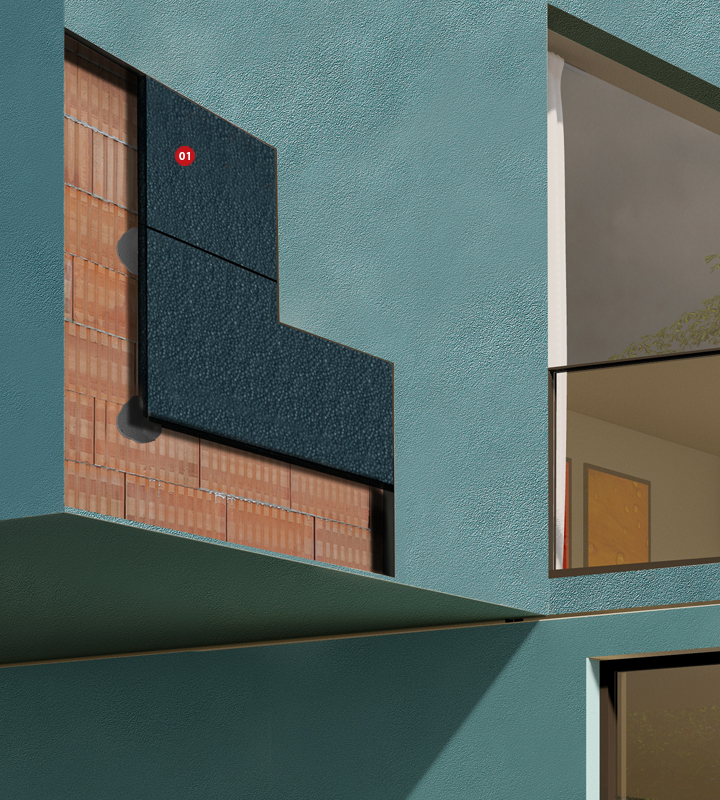

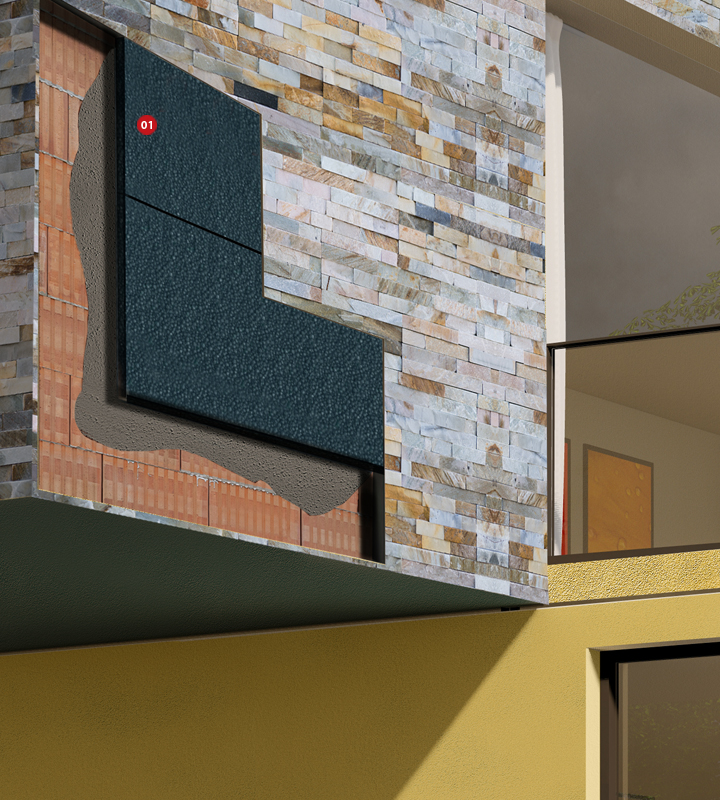

01

licatatherm EPS

White EPS expanded polystyrene thermal insulation panel.

White expanded polystyrene thermal insulation system

licatatherm EPS is a simple and effective thermal insulation system

and effective thermal insulation system using expanded polystyrene sheets

white. With more than 50 years of history, it is extremely

reliable, economical and one of the most popular systems.

Years of experience have greatly contributed to

perfecting licatatherm EPS from a technical and

quality standard.

01

White EPS expanded polystyrene thermal insulation panel.

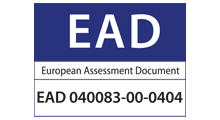

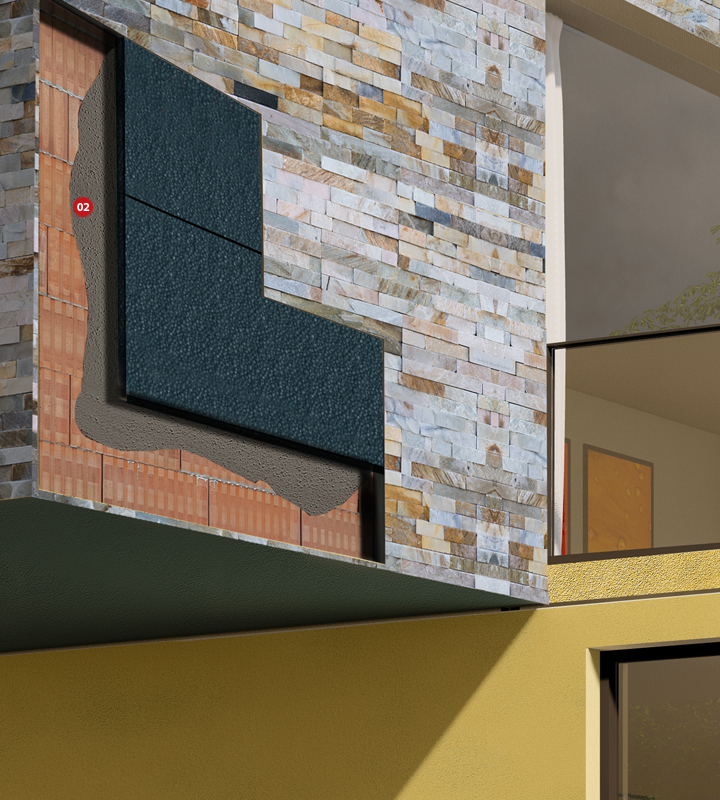

02

Mineral adhesive-smoothing powder for gluing and smoothing insulation panels.

03

licataTHERM percussion or screw anchors made of plastic or steel, for mechanical fastening of insulation panels.

04

licatatherm alkali-resistant fibreglass mesh 160, meets the highest requirements in terms of crack safety and impact resistance.

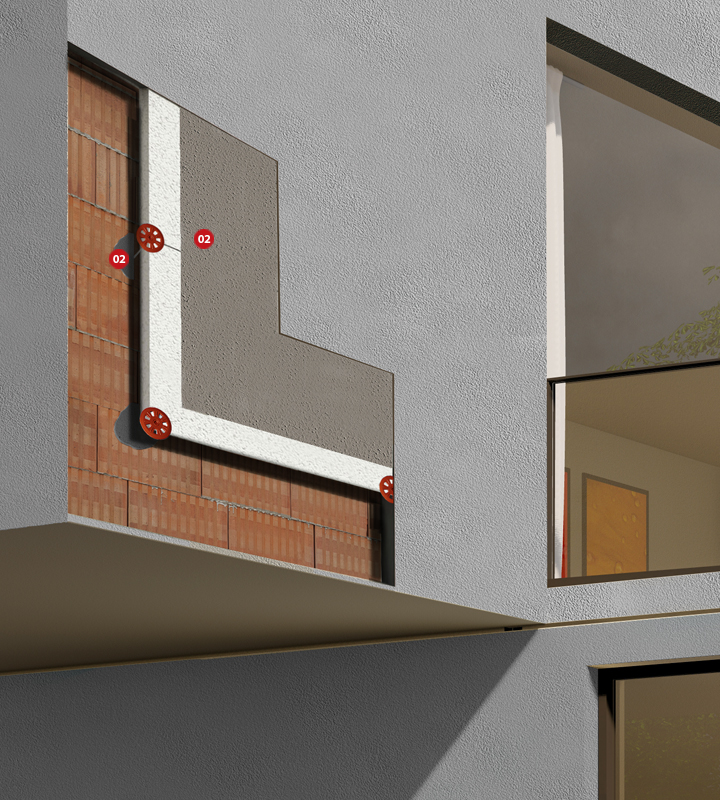

05

Proceed with the second coat of Raso Top 800 skim coat to completely cover the reinforcement mesh.

06

Pigmentable primer based on siloxane copolymers and silica aggregates; specific for exteriors with high breathability and excellent covering properties.

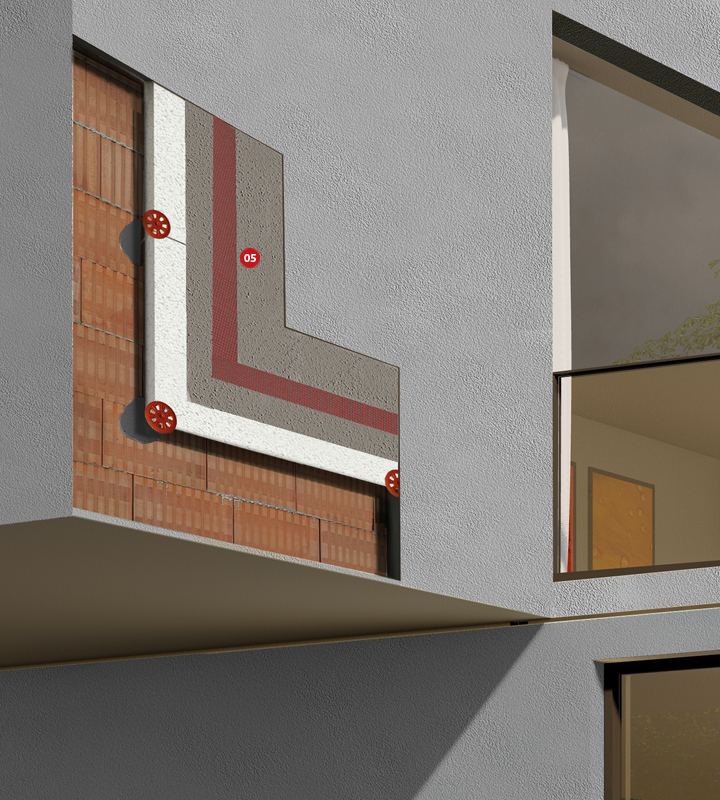

07

Ready-to-use decorative coating paste, based on acrylic, acrylic-siloxane and siloxane resins in water dispersion, resistant to mould and algae attack, with high water repellency and vapour permeability. Ideal as decorative façade protection and in ETICS licataTHERM systems, certified according to ETAG 004.

Expanded polystyrene thermal insulation system with graphite added.

licatatherm EPS with graphite is a thermal insulation system in

which uses expanded polystyrene sheets with graphite added

with graphite in order to enhance the degree of effectiveness even at

reduced thicknesses compared to the traditional EPS system.

licatatherm EPS with graphite when combined with a siloxane finish,

guarantees excellent mechanical resistance to impact, excellent

breathability and high resistance to dirt.

01

Thermal insulation panel made of expanded polystyrene with graphite added.

02

Mineral adhesive-smoothing powder for gluing and smoothing insulation panels.

03

Insulation fixings licatatherm percussion or screwing in plastic or steel, for mechanical fastening of insulation panels.

04

05

Proceed with the second coat of Raso Top 800 skim coat to completely cover the reinforcement mesh.

06

Pigmentable primer based on siloxane copolymers and aggregates of silica nature; specifically for exterior use, with high breathability and excellent covering properties.

07

Ready-to-use decorative coating paste, based on acrylic, acrylic-siloxane and siloxane resins in water dispersion, resistant to mould and algae attack, highly water-repellent and vapour-permeable. Ideal as decorative façade protection and ETICS licataTHERM, systems, certified according to ETAG 004.

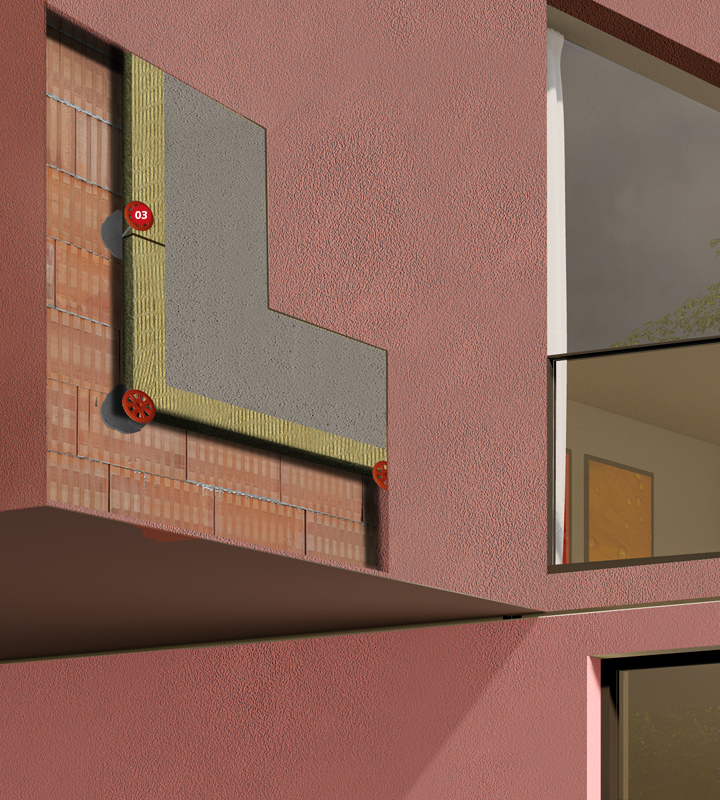

Thermal insulation system with high-density, non-combustible panel for thermal/acoustic insulation.

licatatherm Rockwool is a thermal-acoustic insulation system

insulation system consisting of mineral components such as the

stone wool panel, adhesive-sanding and mineral coatings based on

based potassium silicate according to DIN 18363 LicataSil.

licatatherm stone wool is therefore a system

extremely breathable, robust, durable and totally

non-flammable:

- combines thermal insulation properties with acoustic properties

- excellent protection from both cold and heat

- high panel breathability

- fire-retardant system in class A2 - s1, d0

01

High-density mineral insulation board made of crepe fibre, water-repellent. licataTHERM Rock wool is a high-density insulation board without coating, manufactured in Italy with at least 80 % recycled glass.

02

System adhesives:

1. Raso Top 800 mineral adhesive-smoothing powder for gluing and smoothing insulation panels.

2. Raso Top Bio fibre-reinforced mineral skim coat/glue based only on natural hydraulic lime (NHL 5) certified according to UNI EN 459-1.

03

Insulation fixings licatatherm percussion or screwing in plastic or steel, for mechanical fastening of insulation panels.

04

Alkali-resistant glass fibre netting, fulfils the highest requirements in terms of crack safety and impact resistance.

05

Proceed with the second coat of Raso Top 800 skim coat to completely cover the reinforcement mesh.

06

Pigmentable primer based on siloxane copolymers and aggregates of silica nature; specifically for exterior use, with high breathability and excellent covering properties.

07

Ready-to-use decorative coating paste, based on acrylic, acrylic-siloxane and siloxane resins in water dispersion, resistant to mould and algae attack, highly water-repellent and vapour-permeable. Ideal as decorative façade protection and in ETICS licataTHERM, systems, certified according to ETAG 004.

Reinforced thermal insulation system suitable for surface laying of stone or ceramic cladding.

The licatatherm Strong system is intended for buildings up to 10 m high with:

- The ceramic or stone cladding shall have a reflection index greater than 20%;

- The ceramic or stone cladding shall have a weight ≤ 35 kg/m²;

- The stone cladding shall have a maximum thickness of 5 cm;

- The ceramic cladding shall have a maximum thickness of 2 cm.

01

Thermal insulation panel made of expanded polystyrene with graphite added.

02

System adhesive:

Raso Top 800: cement-based mineral adhesive/rastifier

03

1 reinforced smoothing

After curing for a minimum of three days, the insulation panels will be covered on site with a thin layer of Raso Top 800 mineral adhesive/thickness of approx. 3 mm, in which a glass fibre mesh will be embedded, licataTHERM mesh 160 in ETAG 004.

2 reinforced smoothing

Apply a second layer of Raso Top 800 mineral adhesive/thickener, approx. 3 mm thick, into which a glass fibre mesh will be embedded, licataTHERM rete from 160 certified in ETAG 004.

04

licataTHERM 160 mm net in ETAG 004 for external thermal insulation systems (ETICS). The net will be laid with the edges overlapping by at least 10 cm.

05

Immediately afterwards, insert the appropriate licataTHERM TERMOZ CS 8 plugs and screw them in with a screwdriver until they are flush with the surface.

06

After curing for a minimum of two days, a third coat of Raso Top 800, will be applied to completely cover the dowel rosette and the 530 mm licataTHERM rete da 530 reinforcement mesh.

07

After curing for at least 14 days (at T: +20 °C ±1 and RH: 70% ± 5), proceed with laying stone or ceramic cladding. For this purpose, use high-performance deformable (or highly deformable) cement-based adhesives classified as C2TE-S1 or S2 according to UNI EN 12004 and UNI EN 12002.